Pharmaceutical Cleanroom Products: Manufacturer, Supplier

We are one of the pioneers in the manufacturing of flameproof cleanroom products expressly, for the pharmaceutical sector. The use of latest technology and modern techniques is made for the manufacturing and supplying of best quality products. Our experienced and skilled staff gets trained with trending changes prevalent in the industry for designing of such products and we produce these equipment considering the industry standards and other parameters so that high quality cleanroom products get manufactured from our end.

Cleanrooms are highly controlled environments used in a wide range of industries including pharmaceuticals, biotechnology, microelectronics and medical devices manufacturing. Cleanrooms are specialized facilities that are designed to minimize the number of particles and other contaminants in the air and on surfaces in order to maintain a sterile or controlled environment.

Cleanroom products are specialized equipment and accessories designed to maintain the cleanliness and integrity of cleanroom environments. Cleanroom products are classified according to their level of cleanliness based on the number and size of particles that they can filter out. The International Organization for Standardization (ISO) has established a set of standards for classifying cleanroom environments ranging from ISO Class 1 (the cleanest) to ISO Class 9 (the least clean). Cleanroom products are typically manufactured using specialized materials and manufacturing processes to ensure their cleanliness and compatibility with cleanroom environments. For example, cleanroom gloves are often made from latex-free, powder-free materials and are washed and packaged in cleanroom environments to prevent contamination.

Some of the types of cleanroom products can be mentioned in the below manner:

- Cleanroom garments: These are specialized clothing items for use by workers in cleanrooms to minimize the release of pollutants from their clothing into the air. Cleanroom garments can include full body covers, hoods, gloves, face masks and so on.

- Cleanroom cleaning objects: These are functional cleaning tools that are formulated to reduce the discharge of small microbes and other contaminants during the cleaning process. Examples of cleanroom cleaning supplies include mops, wipes, disinfectants and vacuum.

- Cleanroom furniture: This includes special furniture designed for use in cleanrooms such as tables, chairs and cabinets. Cleanroom furniture reduces the release of dirt, dust and other contaminants from the furniture itself.

- Cleanroom packaging: This refers to packaging materials and items that are fabricated to decrease the transmission of dust particles and other contaminants from the packaging items into the cleanroom environment. Examples of cleanroom packaging materials include bags, containers, and labels.

- Cleanroom equipment: This includes unique equipment manufactured for use in cleanrooms such as air showers, laminar flow hoods and cleanroom ovens. Cleanroom equipment is devised to curtail the release of particles and other contaminants from the equipment itself.

- Cleanroom supplies: This refers to a broad category of products and supply items useful in cleanrooms, including gloves, swabs, filters, and adhesives. The important function of cleanroom supplies is to minimize the release of dust particles and other contaminants into the cleanroom environment.

In conclusion, cleanroom products play a critical role in maintaining the cleanliness and sterility of cleanroom environments. Some of the equipment manufactured and supplied from our end include the following:

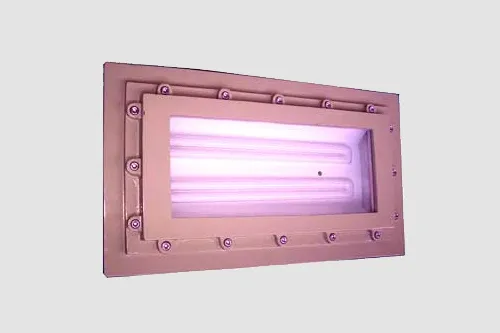

- Clean room fitting top /button , opening suitable for 2x36w CPL, with /without SS cladding.

- Push Button Station, With SS Cladding For Clean Room Application.

- Switch Socket Compressed With SS Cladding For Clean Room Application.

Cleanroom products include various types of equipment, such as air filters, laminar flow hoods, and cleanroom gloves. Air filters are used to remove particulate and other contaminants from the air, while laminar flow hoods provide a controlled environment for working with sterile materials. Cleanroom gloves are designed to prevent the transfer of contaminants from the wearer's hands to the products being handled. Other types of cleanroom products include cleanroom apparel, such as gowns, coveralls, and shoe covers, as well as cleanroom mats, wipes, and disinfectants. Cleanroom apparel is designed to minimize the release of particles and other contaminants from the wearer's body, while cleanroom mats and wipes are used to maintain the cleanliness of the cleanroom floor and surfaces. Disinfectants are used to clean and sanitize the cleanroom environment. In summary, cleanroom products are specialized equipment and supplies designed to maintain the cleanliness and integrity of cleanroom environments. They include air filters, laminar flow hoods, cleanroom gloves, apparel, mats, wipes, and disinfectants. Cleanroom products are classified based on their level of cleanliness and are manufactured using specialized materials and processes to ensure their compatibility with cleanroom environments.

Cleanroom products refer to a wide range of items that are designed and manufactured for use in cleanroom environments. These environments are typically found in industries such as electronics, pharmaceuticals, biotechnology, aerospace, and medical device manufacturing. Cleanrooms are specialized facilities that are designed to minimize the number of particles and other contaminants in the air and on surfaces in order to maintain a sterile or controlled environment. Cleanroom products are essential to maintaining this environment and preventing contamination.

Some common types of cleanroom products include:

- Clean room fitting top /button , opening suitable for 2x36w CPL, with /without SS cladding.

- Push Button Station, With SS Cladding For Clean Room Application.

- Switch Socket Compressed With SS Cladding For Clean Room Application.